Flat Round Head Semi-hollow Rivet

©Nxlon.com D/T:

Structural Features of the Flat Round Head Semi-hollow Rivet

Head Shape: The head is flat and round. Compared with the round head rivet, its top is flatter and has a smaller arc. After riveting, it can make the connected surface relatively flat. At the same time, it is more rounded than the head of the flat head rivet. It is more suitable for occasions where there are certain requirements for appearance and stress dispersion is needed.

Shank Structure: The shank is cylindrical, with a hollow part in the middle. Generally, it is hollow from the head to the middle position. This semi-hollow structure makes it easy for the hollow part of the rivet to expand and deform outward when being riveted under extrusion, which is convenient for filling the riveting hole, forming a firm connection, and can reduce the weight to a certain extent.

Material Selection of the Flat Round Head Semi-hollow Rivet

Carbon Steel: It has relatively high strength and hardness and can withstand large tensile and shear forces. It is suitable for occasions in the general industrial field where the requirements for connection strength are high and the requirements for corrosion resistance are not strict, such as the connection of some common mechanical components. The cost is relatively low, but it is easy to rust in a humid environment or in the presence of corrosive media. Usually, anti-corrosion treatments such as galvanizing and painting are required.

Stainless Steel: It has excellent corrosion resistance and oxidation resistance and can maintain good performance under harsh environmental conditions. It is often used in industries such as food processing, chemical engineering, and medical devices, where strict requirements for hygiene and corrosion resistance are imposed. The flat round head semi-hollow rivets made of stainless steel can ensure that they will not be corroded during long-term use and guarantee the reliability of the connection. However, the cost of stainless steel materials is relatively high.

Aluminum Alloy: It has the characteristics of low density and light weight, and also has a certain degree of corrosion resistance. It is widely used in fields such as aerospace and electronic equipment manufacturing. It can not only meet the requirements for connection strength but also effectively reduce the weight of products, which is of great significance for improving the performance of aerospace vehicles and the portability of electronic equipment.

Manufacturing Process of the Flat Round Head Semi-hollow Rivet

Cold Heading: Usually, the cold heading process is adopted to process the metal material into the approximate shape of the rivet. By applying high pressure to the metal blank at room temperature, it undergoes plastic deformation to form the head and shank of the rivet. This process can increase the density and strength of the metal and ensure the dimensional accuracy and surface quality of the rivet.

Punching: Punching operation is carried out on the rivet blank after cold heading to form a semi-hollow structure. The accuracy of punching is crucial for the performance and quality of the rivet. The diameter, depth, and position of the punching need to be strictly controlled to ensure that the rivet can expand evenly and fill the riveting hole well during riveting.

Surface Treatment: According to the usage environment and requirements, surface treatment is carried out on the rivet. Common surface treatment methods include galvanizing, nickel plating, chromium plating, etc. These treatments can improve the corrosion resistance, wear resistance, and aesthetic appearance of the rivet. In addition, there are some special surface treatment processes, such as Dacromet treatment and phosphating treatment, which can be selected according to specific needs.

Application Fields of the Flat Round Head Semi-hollow Rivet

Automobile Manufacturing: In the manufacturing of automobile bodies, it is often used to connect the thin plate components of the body, such as doors, engine hoods, and trunk lids. Its flat round head design can make the surface of the connected part relatively flat and have a high aesthetic appearance. At the same time, the semi-hollow structure can reduce the weight of the body on the premise of ensuring the connection strength, which helps to improve the fuel economy of the automobile. In addition, it is also applied in the assembly of automobile interior components, such as the connection of seat frames and dashboard brackets.

Electronic Equipment: It is suitable for the assembly of the casings of electronic equipment and the connection of internal structural components. For example, the casings of products such as mobile phones, tablets, and laptops usually use flat round head semi-hollow rivets for fixing, which can not only ensure the firmness of the connection but also make the appearance of the equipment neater and more beautiful. Moreover, in the installation of some small electronic components, this kind of rivet can also give full play to its advantages, making it convenient for riveting operations in a narrow space.

Architectural Decoration: It has certain applications in the field of architectural decoration, such as the installation of metal curtain walls, the assembly of aluminum alloy doors and windows, and the fixing of ceilings. The flat round head semi-hollow rivets can firmly connect metal plates or components together, and their appearance is relatively beautiful, which can meet the requirements for both aesthetics and quality in architectural decoration.

Aerospace: In the aerospace field, although the requirements for the performance of rivets are extremely high, the flat round head semi-hollow rivets are also used in some non-critical structural parts or places where the requirements for connection strength are relatively low. For example, in the connection of the interior panels of an aircraft and the fixing of some lightweight structural components, by taking advantage of their light weight and convenient connection characteristics, it helps to reduce the overall weight of the aircraft and improve its flight performance.

Marking Method of the Flat Round Head Semi-hollow Rivet

The marking of the flat round head semi-hollow rivet usually includes information such as the product name, standard number, nominal diameter, nominal length, material, and surface treatment. For example, the marking "Rivet, Flat Round Head Semi-hollow, GB/T xxx - xxxx, 4×12 - 304 Stainless Steel, Nickel Plated" indicates a flat round head semi-hollow rivet with a nominal diameter of 4mm, a nominal length of 12mm, a material of 304 stainless steel, and a surface treatment of nickel plating. Among them, GB/T xxx - xxxx is the corresponding national standard number. Different types and specifications of flat round head semi-hollow rivets should be marked in accordance with the corresponding standards for easy identification and selection.

Installation Precautions of the Flat Round Head Semi-hollow Rivet

Aperture and Hole Depth: The diameter of the installation hole on the connected part should match the nominal diameter of the rivet, generally slightly larger than the diameter of the shank of the rivet to facilitate the insertion of the rivet. The hole depth should be determined according to the length of the rivet and the thickness of the connected part to ensure that after riveting, the flat round head of the rivet closely fits the surface of the connected part, and the hollow part of the shank can fully expand and fill the riveting hole.

Riveting Tools and Pressure: Select appropriate riveting tools according to the material and specifications of the rivet, such as pneumatic riveting machines, hydraulic riveting machines, or manual rivet guns. During the riveting process, accurately control the riveting pressure. If the pressure is too small, the rivet may not be closely combined with the connected part, affecting the connection strength; if the pressure is too large, it may cause excessive deformation of the rivet head, breakage of the shank, or damage to the connected part.

Verticality and Concentricity: When inserting the rivet into the installation hole, ensure that the axis of the rivet is perpendicular to the surface of the connected part and concentric with the installation hole. This can enable the rivet to be evenly stressed during riveting, ensure that the flat round head fits flatly on the surface of the connected part, and make the shank closely fit the hole wall, improving the stability and strength of the connection.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

R2024-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2024

R2024-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

内3.2外7.0黑色塑料直通柱ABS隔离柱

订购链接:Nxlon.com/1013

国标圆形直通柱垫片垫圈材质:塑料ABS树脂;内径:M3系列=3.2mm,M4系列内径=4.2mm;外径:M3M4系列外径都是7mm;高度:2到15mm

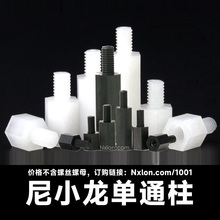

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

绝缘塑料法兰螺母

订购链接:Nxlon.com/1034

尼龙法兰螺母的螺纹规格有:M3*0.5、M4*0.7、M5*0.8、M6*1.0、M8*1.25、M10*1.5、M12*1.75等白色尼龙螺母、黑色塑料螺母、透明塑料法兰螺母。

R3560-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3560

R3560-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

尼龙飞机头内螺纹扣式六角隔离柱

订购链接:Nxlon.com/1005

尼龙飞机头内螺纹扣式六角隔离柱是一种用于电子设备等领域的塑料紧固件,一端为类似飞机头的形状塑料铆钉,这种造型便于扣紧电路板等部件。使用时,先将基板钻孔,再将隔离柱插入孔中,飞机头部分可以卡紧电路板,起到稳固的作用。