Round-head Grooved Pin

©Nxlon.com D/T:

The round-head grooved pin is a common mechanical connection and positioning part. The following is the relevant introduction of the round-head grooved pin:

Structural Features of the Round-head Grooved Pin

Head: It is round and relatively smooth. This design can prevent scratches on the human body or other components during installation and use. At the same time, it is also beneficial for use in some occasions where aesthetics are required.

Grooves: There are longitudinal grooves along the length direction of the pin body, and these grooves are usually evenly distributed. The function of the grooves is that after the pin is inserted into the pin hole, the elastic deformation of the grooves can be used to adapt to different hole diameter tolerances, improving the tightness and reliability of the connection. At the same time, the grooves can also increase the friction between the pin and the connected components, preventing the pin from loosening during use.

Pin Body: Generally, it is cylindrical, and the surface is usually processed to have a certain precision and surface finish to ensure the fitting accuracy with the pin hole.

Materials and Properties of the Round-head Grooved Pin

Materials: Medium carbon steel or medium carbon alloy steel is usually used, such as 45 steel, 40Cr, etc. These materials have good strength and toughness and can meet the usage requirements of general mechanical connections. For some occasions with special requirements, stainless steel or other special materials are also used for manufacturing to improve the corrosion resistance, wear resistance and other properties of the pin.

Properties

High Strength: It can withstand large shear force and tensile force to ensure the firmness of the connection.

Good Toughness: It is not easy to undergo brittle fracture under impact or vibration loads, improving the safety of use.

Good Wear Resistance: After appropriate heat treatment and surface treatment, the round-head grooved pin has good wear resistance and can maintain good performance during long-term use.

Application Fields of the Round-head Grooved Pin

Mechanical Manufacturing: It is widely used in the assembly of various mechanical equipment for connecting and positioning different parts, such as the connection between gears, chain wheels, pulleys and shafts, as well as the connection and positioning between various casings, brackets and other components.

Automobile Industry: It is often used in the assembly of components such as automobile engines, transmissions, and chassis. For example, it is used to fix engine components and connect the components of the chassis suspension system, etc., to ensure the accurate installation and reliable connection of various components of the automobile.

Aerospace: It is also applied in aspects such as aircraft structure assembly and engine manufacturing. Due to its high reliability, it can meet the high-precision and high-reliability requirements for the connection of components in the aerospace field.

Other Fields: In industries such as electronic equipment manufacturing, instrument manufacturing, and furniture manufacturing, the round-head grooved pin is also used in various occasions that require connection and positioning, such as the assembly of electronic equipment casings, the fixing of components in instruments, and the auxiliary connection of mortise and tenon structures in furniture.

Specifications and Dimensions of the Round-head Grooved Pin

The specifications and dimensions of the round-head grooved pin usually include parameters such as diameter, length, and the number and dimensions of the grooves.

Diameter: Common diameter specifications are 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, etc. For different application occasions, an appropriate diameter needs to be selected according to the hole diameter of the connected parts and the force-bearing situation.

Length: The length generally ranges from 6mm to 200mm, and the specific length is determined according to the thickness of the actually connected parts and the installation requirements.

Parameters of the Grooves: The number of grooves is usually 3, 4, or 6, etc., and the width and depth of the grooves also have corresponding standard dimensions to ensure the elasticity and connection performance of the pin.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

尼小龙塑料SB通孔扣式护线套

订购链接:Nxlon.com/1051

绝缘塑料SB通孔扣式护线套16-19-22-25尼龙电缆电源线塑胶线孔盖质:尼龙,颜色:黑色、白色;规格:SB-16、SB-19、SB-22、SB-25等。

绝缘透明塑料六角螺母

订购链接:Nxlon.com/1016

绝缘透明塑料六角螺母是一种采用聚碳酸酯(PC)材料制成的具有特定功能和特性的塑料螺母,尼小龙现有塑料螺母M3、M4、M5、M6、M8等公制规格。

内4.2外7.0白色塑料直通柱隔离柱

订购链接:Nxlon.com/1014

内4.2外7.0塑料直通柱隔离柱是一种用于电子设备等领域的绝缘零部件,尼小龙现有直通柱M4系列内径=4.2mm;外径:M4系列外径都是7mm;高度:2到15mm

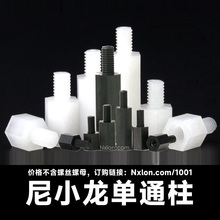

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

塑料螺丝保护套-螺母保护帽

订购链接:Nxlon.com/1035

塑料螺丝帽保护套-塑料螺母保护帽M8M10六角塑料螺母保护帽外六角塑料螺丝盖罩螺栓螺丝装饰防尘套,尼小龙螺母保护帽材质:聚丙烯 Polypropylene,型号:S-12-PP, S-13-PP, S-14-PP, S-16-PP, S-17-PP