Hexagon Flange Face Self-drilling and Self-tapping Screw

©Nxlon.com D/T:

The hexagon flange face self-drilling and self-tapping screw is a kind of fastener with special structure and function. The following is a detailed introduction to the hexagon flange face self-drilling and self-tapping screw:

Structural Features of the Hexagon Flange Face Self-drilling and Self-tapping Screw

Hexagon Flange Face: The head of the screw is hexagonal with a flange face. The hexagonal head is convenient for tightening and disassembling operations using tools such as wrenches, providing a larger torque application area. The flange face increases the contact area between the screw and the surface of the connected component, which can better disperse the pressure, prevent damage to the surface of the connected component during the tightening process, and also improve the sealing performance and anti-loosening performance of the connection.

Self-drilling Function: The front end of the screw has a cutting edge in the shape of a drill bit. During installation, there is no need to pre-drill a hole in the connected component. The drill bit part of the screw itself can be directly used to drill a suitable hole in the material, and then it can be continuously screwed in to form a threaded connection, which greatly improves the installation efficiency, especially suitable for on-site construction or occasions where pre-drilling is difficult.

Self-tapping Thread: The thread part adopts a special tooth profile design, which can extrude an internal thread on the material of the connected component by itself during the screwing-in process. This self-tapping thread has a tight fit with the material of the connected component, and the connection strength is relatively high, which can effectively prevent the screw from loosening and ensure the reliability of the connection.

Materials and Surface Treatment of the Hexagon Flange Face Self-drilling and Self-tapping Screw

Materials: It is usually made of high-quality carbon steel or stainless steel. Carbon steel materials have high strength and hardness, which can meet the connection strength requirements in general engineering applications, and the cost is relatively low. Stainless steel materials have excellent corrosion resistance and oxidation resistance, and are suitable for corrosive environments such as humidity, acid and alkali, such as in the fields of chemical equipment, marine engineering, food processing equipment, etc., which can ensure that the screws will not rust or be damaged during long-term use under harsh conditions.

Surface Treatment: In order to further improve the performance and service life of the screws, surface treatment is generally carried out on them. Common surface treatment methods include galvanizing, nickel plating, blackening, etc. Galvanizing treatment can improve the corrosion resistance of the screws. Nickel plating treatment can not only enhance the corrosion resistance but also make the surface of the screws more beautiful and smooth. Blackening treatment is mainly used in some occasions with special requirements for appearance or where an increase in surface hardness is required.

Specifications and Dimensions of the Hexagon Flange Face Self-drilling and Self-tapping Screw

Thread Specifications: Common ones include M4, M5, M6, M8, etc. Different thread specifications are suitable for different connection strength requirements and the thickness of the connected components. Smaller specifications such as M4 and M5 are suitable for connecting thinner plates or occasions with high requirements for space, while larger specifications such as M6 and M8 can be used for connecting thicker steel plates or structural components with high requirements for connection strength.

Length Dimensions: The length generally ranges from 16mm to 100mm. The specific length can be selected according to the total thickness of the connected components and the actual installation space. For example, for connecting two layers of thinner steel plates, screws with a length of 20mm or 30mm may be selected; while for connecting multiple layers of thick steel plates or in cases where it is necessary to penetrate thicker materials, longer screws such as 50mm, 80mm or even longer specifications are required.

Application Fields of the Hexagon Flange Face Self-drilling and Self-tapping Screw

Construction Industry: In steel structure buildings, it is used to connect various structural steel, steel plates and other components, such as the connection of roof trusses, purlins, wall beams, etc. Its self-drilling and self-tapping characteristics enable quick and convenient installation at the construction site, improving the construction efficiency. In the installation of building curtain walls, it is also often used to connect and fix the curtain wall frame to the main structure to ensure the stability and safety of the curtain wall.

Automobile Manufacturing: During the assembly process of automobile bodies, it is used to connect the thin plate parts of the body, such as the components of the car doors, engine hoods, luggage compartment lids, etc. The hexagon flange face self-drilling and self-tapping screws can quickly connect thin plate materials without pre-drilling, and have good vibration resistance, which can ensure the firmness of the body structure during the driving process of the automobile.

Electronic Equipment Manufacturing: It is applied in the assembly of the casings of some electronic equipment, such as computer cases, server cabinets, etc. It can quickly connect and fix the various parts of the casing. At the same time, due to its smaller specifications and good connection performance, it can meet the requirements of electronic equipment for the connection accuracy and reliability of components.

Furniture Manufacturing: It is used to connect the metal parts of furniture or the connection between panel parts and metal fittings. For example, in the assembly of some metal furniture, it can connect components such as table legs and chair backs to the frame; in panel furniture, it is used to fix the hardware connectors to the panels, enhancing the structural stability of the furniture.

Installation Precautions for the Hexagon Flange Face Self-drilling and Self-tapping Screw

Select Appropriate Tools: Use electric or manual tools that match the screw specifications for installation, such as electric screwdrivers, pneumatic wrenches, etc. Ensure that the tools can provide sufficient torque to tighten the screws, but also pay attention to avoid excessive torque causing the screws to break or damaging the connected components.

Control the Drilling Depth: Although the self-drilling and self-tapping screw has a self-drilling function, it is still necessary to control the drilling depth according to the thickness of the connected component to avoid the drill bit penetrating the bottom material or the drilling being too shallow, which will prevent the thread from being fully formed and affect the connection strength.

Pay Attention to the Installation Angle: During installation, keep the screw perpendicular to the surface of the connected component to ensure that the screw can smoothly drill into the material and form a uniform thread, and avoid damage to the thread or insecure connection caused by angle deviation.

Avoid Over-tightening: After the screw is tightened to a certain extent, do not continue to over-tighten it to avoid deforming the flange face or damaging the material of the connected component. Generally speaking, when the flange face of the screw head is closely attached to the surface of the connected component and reaches the specified torque value, the installation can be considered completed.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

R2024-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2024

R2024-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

R4060-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/4060

R4060-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

尼龙飞机头内螺纹扣式六角隔离柱

订购链接:Nxlon.com/1005

尼龙飞机头内螺纹扣式六角隔离柱是一种用于电子设备等领域的塑料紧固件,一端为类似飞机头的形状塑料铆钉,这种造型便于扣紧电路板等部件。使用时,先将基板钻孔,再将隔离柱插入孔中,飞机头部分可以卡紧电路板,起到稳固的作用。

R3560-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3560

R3560-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

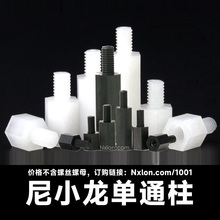

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

内3.2外7.0黑色塑料直通柱ABS隔离柱

订购链接:Nxlon.com/1013

国标圆形直通柱垫片垫圈材质:塑料ABS树脂;内径:M3系列=3.2mm,M4系列内径=4.2mm;外径:M3M4系列外径都是7mm;高度:2到15mm