Hexagon Head Self-extruding Screw

©Nxlon.com D/T:

The hexagon head self-extruding screw is a kind of fastener with unique structural and performance characteristics. The following is the relevant information about the hexagon head self-extruding screw:

Structural Characteristics of the Hexagon Head Self-extruding Screw

Head: It is in a regular hexagonal shape. This shape makes it convenient to operate with a wrench or socket tool, can provide a large torque, effectively avoid the slipping phenomenon, and make the installation and disassembly more convenient and efficient.

Screw Shank: The thread pitch and thread angle are the same as those of ordinary metric screws. However, the end of the thread is designed with a section of thread having an arc-shaped triangular cross-section, which is the key feature of the hexagon head self-extruding screw and is similar to the working principle of an internal thread extruding tap. When screwing into the pre-drilled hole, the three vertices of the triangular cross-section will apply intermittent and periodic pressure to the side wall of the pre-drilled hole, causing the base material on the inner wall of the pre-drilled hole to be extruded and pushed into the thread flanks and the root of the thread along the thread lead, thus forming an internal thread.

Advantages of the Hexagon Head Self-extruding Screw

Low Screw-in Torque: Compared with self-tapping screws, self-extruding screws form internal threads by extrusion during the screwing-in process, while ordinary self-tapping screws form internal threads by cutting. Therefore, the screwing-in frictional resistance of the hexagon head self-extruding screw is much lower than that of ordinary self-tapping screws, and it can be assembled on a thicker section.

High Locking Performance: There is a certain clearance in the fit between the internal and external threads of ordinary metric screws. When the hexagon head self-extruding screw is screwed in, the triangular cross-section at the tail of the thread extrudes the metal to form an internal thread. According to the laws of the minimum resistance of metal plastic deformation and the invariance of volume, the extruded metal fills into the screw threads along the thread lead. The thread fit clearance of this assembly structure is small, and it can even achieve the effect of the metal "locking" the screw. Therefore, it is also known as the "self-tapping locking screw".

Application Scenarios of the Hexagon Head Self-extruding Screw

Automobile Manufacturing: In automobile production, it is used to connect vehicle body structural parts, engine components, etc. Its high locking performance can ensure that during the vehicle's driving process, the components are firmly connected and can withstand vibrations and various stresses.

Electronic Products: It is suitable for the assembly of the casings of electronic devices, the fixing of internal circuit boards, etc. The low screw-in torque can avoid damaging fragile electronic components. At the same time, the good locking performance can ensure that the device will not have loose screws due to vibrations and other reasons during use.

Building Decoration: For example, in some light steel structure buildings, it is used to connect structural components such as steel beams and steel columns; in decoration, it is used to fix keels, decorative panels, etc., which can provide reliable connection strength and ensure the structural stability.

Selection Method of the Hexagon Head Self-extruding Screw

Selection According to the Material: For materials such as non-alloy, low-alloy, aluminum and aluminum alloys, copper and copper alloys (with a copper content greater than 63%), and zinc and zinc alloys with a tensile strength σb ≤ 600 N/mm², hexagon head self-extruding screws of ordinary materials can usually be selected. For materials with poor plastic deformation ability or prone to work hardening, such as stainless steel, gray cast iron, and magnesium alloy, they can also be used under certain usage conditions, but a cautious evaluation is required. If there is a risk of corrosion in the usage environment, such as in a humid environment or when in contact with corrosive media, hexagon head self-extruding screws made of stainless steel should be selected.

Selection According to the Specification: Determine the appropriate diameter and length specifications according to the thickness of the connected parts and the requirements for the connection strength. Generally speaking, when the connected parts are thicker or a greater connection strength is required, screws with a larger diameter and a longer length should be selected; conversely, screws with smaller specifications should be selected. At the same time, it is necessary to ensure that the length of the screw is sufficient to completely pass through the connected parts and form an effective connection, but it should not be too long to avoid excessive exposure, which will affect the appearance or cause potential safety hazards.

Installation Key Points of the Hexagon Head Self-extruding Screw

Pre-drilled Hole Processing: Before installation, a suitable pre-drilled hole needs to be processed according to the screw specification and the material of the connected part. The diameter of the pre-drilled hole needs to be precisely controlled. The diameter of the pre-drilled hole varies slightly for base materials of different materials and thicknesses to ensure the fitting effect between the screw and the pre-drilled hole.

Ensure the Surface is Clean: Clean the surface of the connected part thoroughly to remove impurities such as oil stains, dust, and rust, ensuring good contact between the screw and the surface and improving the reliability of the connection.

Screw in Vertically: Use a suitable tool to screw the screw vertically into the surface of the connected part, avoiding tilting or eccentricity, otherwise it may lead to thread damage or an insecure connection. If an electric tool is used, pay attention to controlling the rotation speed and torque to prevent damage to the screw or the connected part due to too high a rotation speed or too large a torque.

Control the Screw-in Depth: According to the thickness of the connected part and actual needs, control the screw-in depth of the screw well. Avoid screwing in too deeply, which may cause the screw to penetrate the connected part or damage the internal structure, and do not screw in too shallowly to avoid an insecure connection.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

绝缘塑料法兰螺母

订购链接:Nxlon.com/1034

尼龙法兰螺母的螺纹规格有:M3*0.5、M4*0.7、M5*0.8、M6*1.0、M8*1.25、M10*1.5、M12*1.75等白色尼龙螺母、黑色塑料螺母、透明塑料法兰螺母。

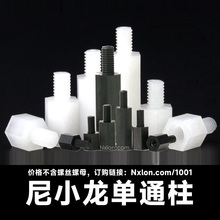

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

R3550-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3550

R3550-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

R3560-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3560

R3560-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

绝缘尼龙十字沉头螺丝

订购链接:Nxlon.com/1017

绝缘尼龙十字沉头螺丝采用知名品牌进口注塑级尼龙PA66、参照国标GB819标准规定的尺寸制造而成。现货沉头塑料螺丝的螺纹规格有:M3*0.5mm、M4*0.7mm等。

内4.2外7.0黑色塑料直通柱隔离柱

订购链接:Nxlon.com/1015

内4.2外7.0塑料直通柱隔离柱是一种用于电子设备等领域的绝缘零部件,尼小龙现有直通柱M4系列内径=4.2mm;外径:M4系列外径都是7mm;高度:2到15mm