Cross Recessed Raised Countersunk Head Self-Extruding Screw

©Nxlon.com D/T:

The cross recessed raised countersunk head self-extruding screw is a relatively special type of screw. The following will introduce it to you from the aspects of structural features, materials and processes, specifications and dimensions, application fields, as well as installation and disassembly:

Structural Features of the Cross Recessed Raised Countersunk Head Self-Extruding Screw

Head Shape: It has a raised countersunk head design. This shape makes the screw head slightly lower than the surface of the connected component after installation, which not only ensures the flatness of the connection but also provides a certain supporting area. Compared with the full countersunk head, the raised countersunk head is more suitable for some occasions where the requirement for surface flatness is not extremely high, but a certain head support is needed.

Slot Design: It adopts a cross recessed slot, which is convenient for operation with a cross screwdriver. The cross recessed slot can transmit torque well, making the tightening and loosening processes smoother. Moreover, compared with the slotted head, it has stronger anti-slip ability, which can effectively prevent the damage to the screw head or the surface of the connected component caused by the slippage of the screwdriver.

Thread Structure: It belongs to a self-extruding screw. Its thread will extrude the material of the connected component during the screwing-in process, thus forming an internal thread that matches it. This thread structure does not require pre-processing a complete internal thread in the connected component, reducing the processing procedures. At the same time, it can also ensure good connection strength and locking performance. The thread of the self-extruding screw usually has a relatively sharp tooth profile to better cut into the material and achieve extrusion molding.

Materials and Processes of the Cross Recessed Raised Countersunk Head Self-Extruding Screw

Material Selection: Generally, high-quality metal materials such as carbon steel and stainless steel are selected. The cross recessed raised countersunk head self-extruding screw made of carbon steel has high strength and hardness, and is suitable for most conventional mechanical connection occasions. The one made of stainless steel has good corrosion resistance and oxidation resistance, and is often used for connections in corrosive environments such as humidity, acid and alkali, such as the connections of outdoor equipment and chemical equipment.

Manufacturing Process: The manufacturing process includes main processes such as cold heading, thread rolling, and heat treatment. The cold heading process is used to form the head and shank of the screw, which can improve the material utilization rate and production efficiency. At the same time, it makes the structure of the metal material more compact and improves the strength of the screw. The thread rolling process is used to process precise threads to ensure the dimensional accuracy and surface quality of the threads. The heat treatment process can further improve the hardness, strength and toughness of the screw to meet the requirements of its mechanical properties in different application scenarios.

Specifications and Dimensions of the Cross Recessed Raised Countersunk Head Self-Extruding Screw

Thread Specifications: Common thread specifications include M2.5, M3, M4, M5, M6, etc. Smaller specifications such as M2.5 and M3 are often used for the assembly of electronic devices, small instruments, etc.; larger specifications such as M5 and M6 are more applied in fields such as machinery manufacturing and furniture manufacturing.

Length Dimensions: The length of the screw is usually between 6mm and 50mm. The specific length can be selected according to the thickness of the connected component and the actual installation space. For example, when connecting thinner plates, shorter screws such as 6mm and 8mm can be selected; while when connecting thicker components or when it is necessary to pass through multiple layers of materials, longer screws such as 30mm and 50mm need to be selected.

Application Fields of the Cross Recessed Raised Countersunk Head Self-Extruding Screw

Electronic Equipment Manufacturing: In the production of electronic equipment, such as mobile phones, tablets, laptops, etc., it is often used to fix components such as circuit boards and casings. Its raised countersunk head design can make the surface relatively flat, avoiding the influence on the appearance and assembly accuracy of the equipment due to the protrusion of the screw head; the characteristics of the self-extruding screw can quickly achieve a firm connection without pre-processing the threaded hole, improving the production efficiency.

Instrument and Meter Manufacturing: For various instruments and meters, the cross recessed raised countersunk head self-extruding screw can be used to connect the casings, panels and internal components of the instruments. Since instruments and meters usually have high requirements for accuracy and stability, the precise fastening performance of this screw can ensure that the connections of all components are firm and reliable during the long-term use of the instrument, and will not loosen due to vibration or other factors, thus ensuring the normal operation of the instrument and the measurement accuracy.

Furniture Manufacturing: During the assembly of furniture, it can be used to connect wooden boards, artificial boards, etc. For example, in the production of wardrobes and cabinets, it is used to fix components such as side panels and partitions. The raised countersunk head design can make the surface of the furniture more flat and beautiful. At the same time, the connection method of the self-extruding screw can provide sufficient connection strength to ensure the structural stability of the furniture.

Automobile Parts Manufacturing: In the production of automobiles, it is suitable for some occasions where high connection strength is required and quick assembly is needed. For example, the installation of automobile interior parts, the fixation of some small components around the engine, etc. Its good fastening performance can ensure that these components will not loosen due to vibration during the driving process of the automobile. At the same time, the cross recessed slot design is convenient for the operation of robots or tools on the automated assembly line, improving the production efficiency.

Installation and Disassembly of the Cross Recessed Raised Countersunk Head Self-Extruding Screw

Installation Method: First, drill a suitable bottom hole in the connected component according to the specification of the screw. The diameter of the bottom hole is usually slightly smaller than the outer diameter of the screw to ensure that the screw can effectively extrude the material when it is screwed in. Then, use a cross screwdriver or an electric screwdriver to align the screw with the bottom hole, and rotate the screwdriver clockwise to gradually screw the screw into the connected component. During the screwing-in process, pay attention to controlling the torque to avoid the breakage of the screw or the damage of the connected component due to excessive torque. When the screw head is flush with or slightly lower than the surface of the connected component, the installation is completed.

Disassembly Method: When disassembling, use a cross screwdriver or an electric screwdriver of the same specification as that used for installation, and rotate the screwdriver counterclockwise to unscrew the screw from the connected component. If the screw is rusted or stuck during use, you can first spray a rust remover around the screw, wait for a period of time to let the rust remover fully penetrate, and then try to disassemble it. During the disassembly process, if there is greater resistance, do not forcefully twist it to avoid damaging the screwdriver or the screw head. You can try to tap the screwdriver gently to loosen the screw and then disassemble it.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

绝缘尼龙垫圈塑料垫片

订购链接:Nxlon.com/1010

绝缘尼龙垫圈塑料垫片是以尼龙为材质的平垫圈,在电子、机械等领域应用广泛,尼龙垫圈材质:尼龙66,颜色:黑色;规格:公称内径*公称外径*公称厚度

塑料螺丝保护套-螺母保护帽

订购链接:Nxlon.com/1035

塑料螺丝帽保护套-塑料螺母保护帽M8M10六角塑料螺母保护帽外六角塑料螺丝盖罩螺栓螺丝装饰防尘套,尼小龙螺母保护帽材质:聚丙烯 Polypropylene,型号:S-12-PP, S-13-PP, S-14-PP, S-16-PP, S-17-PP

R3560-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3560

R3560-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

塑料R型线夹圆形线卡拱形压线板

订购链接:Nxlon.com/1053

塑料R型线夹圆形线卡拱形压线板,材质:PP塑料、尼龙等。紧固孔:M4。塑料R型线夹圆形线卡拱形压线板,材质:PP塑料、尼龙等。紧固孔:M4。

尼小龙EHR塑料花瓣型护线套

订购链接:Nxlon.com/1050

塑料梅花型护线套EHR尼龙扣式线束圈花瓣形保护环卡电线出线孔塞材质:尼龙,颜色:黑色、白色;规格:EHR-16、EHR-19、EHR-21、EHR-22、EHR-25等。

尼龙飞机头内螺纹扣式六角隔离柱

订购链接:Nxlon.com/1005

尼龙飞机头内螺纹扣式六角隔离柱是一种用于电子设备等领域的塑料紧固件,一端为类似飞机头的形状塑料铆钉,这种造型便于扣紧电路板等部件。使用时,先将基板钻孔,再将隔离柱插入孔中,飞机头部分可以卡紧电路板,起到稳固的作用。

绝缘尼龙铆钉-LRD-4-LRD-5塑料卡扣

订购链接:Nxlon.com/1019

绝缘尼龙铆钉-LRD-4-LRD-5塑料卡扣是一种常用于电子行业的紧固件,塑料铆钉直径:3.6mm,塑料铆钉头直径:7mm,公称长度:8.6mm等。

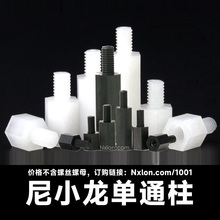

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!