Split Pin

©Nxlon.com D/T:

The split pin is a commonly used mechanical connection and anti-loosening part. The following is a detailed introduction to the split pin:

Definition and Structure of the Split Pin

The split pin is a "U"-shaped metal pin, usually made of low-carbon steel or medium-carbon steel. Some are made of stainless steel to adapt to special environments. One end of it has a small hole, which is used to pass through the hole at the tail of a bolt or nut, and the other end can be opened to form an opening to prevent the connected parts from loosening.

Features of the Split Pin

Good Anti-loosening Performance: It can effectively prevent the loosening of connecting parts such as nuts and bolts under vibration or impact loads, ensuring the reliability of the connection.

Simple Structure: With a simple shape, the manufacturing process is relatively easy, and the cost is low.

Easy Installation: No special tools are required. Just insert the split pin into the corresponding hole and open it to complete the installation.

Reusable: After the connected parts are disassembled, the split pin can usually be reused if it is not damaged.

Manufacturing Standards of the Split Pin

The national standard is GB/T 91-2000 "Split Pins", which stipulates the dimensions, tolerances, materials, surface treatments, etc. of the split pin. For example, it clarifies the dimensional parameters corresponding to different nominal specifications, the mechanical property requirements of the materials, and that the surface should be subjected to galvanized passivation or oxidation treatment, etc.

Materials and Surface Treatments of the Split Pin

Commonly Used Materials: Generally, carbon steels such as Q215 and Q235 are used. When a higher corrosion resistance is required, stainless steel materials such as 1Cr18Ni9Ti are selected.

Surface Treatments: Common ones include galvanizing, cadmium plating, etc., which can improve the corrosion resistance of the split pin and extend its service life. In addition, there is also oxidation treatment, which forms an oxide film on the surface to play a certain anti-rust role.

Application Fields of the Split Pin

Mechanical Field: Widely used in the connection parts of various mechanical equipment, such as gearboxes, engines, cranes, etc., to prevent the loosening of connecting parts such as bolts and nuts.

Automotive Industry: Often used in the connection of parts such as the chassis, engine, and body of automobiles to ensure the safe and reliable connection of various components during the driving process of the automobile.

Railway Transportation: Used in the connection of railway tracks, the bogies of vehicles, etc., to ensure the stability of the railway system under high-speed operation and vibration conditions.

Construction Machinery: In the connection parts of equipment such as tower cranes and concrete mixers, the split pin plays an important anti-loosening role, ensuring the safe operation of the equipment.

Marking Method of the Split Pin

The marking content includes information such as the product name, nominal specification, length, material, and surface treatment. For example, the marking "Split Pin GB/T 91 5×50 Q235 - Zn" indicates a split pin with a nominal specification of 5mm, a length of 50mm, a material of Q235 steel, and a surface treatment of galvanizing.

Purchase Precautions for the Split Pin

Size Matching: According to the hole diameter and slot width of the actually used connecting parts such as bolts and nuts, select a split pin with an appropriate nominal specification to ensure a tight fit.

Material Selection: Select a split pin with an appropriate material according to the corrosion degree, temperature, and other conditions of the use environment. For example, in a humid environment, a split pin made of stainless steel should be selected.

Quality Inspection: Check the appearance of the split pin, which should have no defects such as cracks, burrs, and deformations. At the same time, check whether its hardness and toughness meet the requirements, and a preliminary judgment can be made through a simple bending test.

Installation and Maintenance of the Split Pin

Installation: First, insert the split pin into the hole at the tail of the bolt or nut, and then use a tool to open the tail of the split pin so that the opening angle meets the requirements. Generally, the opening angle is 60° - 90°. When installing, ensure that the split pin is completely inserted into the hole and the opening is uniform and symmetrical.

Maintenance: Regularly check the status of the split pin. If the split pin is found to be loose, deformed, corroded, or damaged, etc., it should be replaced in a timely manner. When the equipment is overhauled or maintained, the split pin should also be checked and maintained to ensure that it is always in good working condition.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

塑料螺丝保护套-螺母保护帽

订购链接:Nxlon.com/1035

塑料螺丝帽保护套-塑料螺母保护帽M8M10六角塑料螺母保护帽外六角塑料螺丝盖罩螺栓螺丝装饰防尘套,尼小龙螺母保护帽材质:聚丙烯 Polypropylene,型号:S-12-PP, S-13-PP, S-14-PP, S-16-PP, S-17-PP

绝缘塑料法兰螺母

订购链接:Nxlon.com/1034

尼龙法兰螺母的螺纹规格有:M3*0.5、M4*0.7、M5*0.8、M6*1.0、M8*1.25、M10*1.5、M12*1.75等白色尼龙螺母、黑色塑料螺母、透明塑料法兰螺母。

R2648-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2648

R2648-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

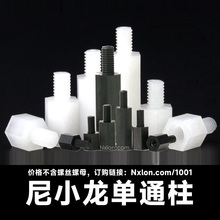

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

R2642-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2642

R2642-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

内3.2外7.0黑色塑料直通柱ABS隔离柱

订购链接:Nxlon.com/1013

国标圆形直通柱垫片垫圈材质:塑料ABS树脂;内径:M3系列=3.2mm,M4系列内径=4.2mm;外径:M3M4系列外径都是7mm;高度:2到15mm

R2655-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2655

R2655-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

尼龙飞机头内螺纹扣式六角隔离柱

订购链接:Nxlon.com/1005

尼龙飞机头内螺纹扣式六角隔离柱是一种用于电子设备等领域的塑料紧固件,一端为类似飞机头的形状塑料铆钉,这种造型便于扣紧电路板等部件。使用时,先将基板钻孔,再将隔离柱插入孔中,飞机头部分可以卡紧电路板,起到稳固的作用。