Light-duty Rolled Elastic Cylindrical Pin

©Nxlon.com D/T:

The light-duty rolled elastic cylindrical pin is a mechanical connecting piece with specific structural and performance characteristics. The following is a detailed introduction to the light-duty rolled elastic cylindrical pin:

Definition and Structure of the Light-duty Rolled Elastic Cylindrical Pin

The light-duty rolled elastic cylindrical pin is a hollow cylindrical pin manufactured through a rolling process. It is usually made of elastic materials, with an axial slot and chamfers at both ends. Its unique structure enables it to generate radial tension after installation, thus firmly fixing it in the assembly hole.

Features of the Light-duty Rolled Elastic Cylindrical Pin

Good Elasticity: It can undergo elastic deformation under a relatively small external force, effectively buffering and absorbing impact energy, and can return to its original shape after the external force is removed.

Convenient Installation: Its outer diameter is slightly larger than the assembly hole diameter. It can be gently tapped or pressed into the hole without the need for additional fastening devices, and the installation process is simple and efficient.

Precise Positioning: It can provide relatively accurate positioning for parts, ensuring the accuracy and stability of the connection and reducing assembly errors.

Reusable: Under reasonable usage conditions, if the elastic performance is not severely damaged after disassembly, it can be used again, reducing the usage cost.

Manufacturing Standards of the Light-duty Rolled Elastic Cylindrical Pin

The national standard is GB/T 879.5-2018 "Elastic Cylindrical Pins - Rolled - Light-duty", which clearly stipulates its dimensions, tolerances, materials, surface treatments, and technical requirements. For example, it specifies the length series corresponding to different nominal diameters, as well as the mechanical property requirements of the materials, etc.

Materials and Surface Treatments of the Light-duty Rolled Elastic Cylindrical Pin

Commonly Used Materials: Generally, spring steels such as 65Mn are used, which have high strength and good elasticity. In occasions with requirements for corrosion resistance, stainless steel materials such as 304 stainless steel and 316 stainless steel are used.

Surface Treatments: Common ones include electroplating, such as zinc plating, nickel plating, and chromium plating, which can improve corrosion resistance and wear resistance and increase the surface hardness. Phosphating treatment is also used to form a phosphate protective film, playing a role in rust prevention and lubrication. In some cases, a non-electrolytic zinc flake coating will be added to steel elastic pins, and stainless steel elastic pins will be passivated.

Application Fields of the Light-duty Rolled Elastic Cylindrical Pin

Connection of Plastic Parts: It is often used for the connection and fixation of plastic hinges and plastic parts. For example, in the connection between the housing of the gear shift lever of an automobile transmission and the base, it can provide a reliable connection without damaging the plastic parts.

Assembly of Electronic Equipment: In electronic equipment, it can be used to fix circuit boards, small components, etc., meeting the requirements of miniaturization and high precision of electronic equipment.

Manufacturing of Instruments and Meters: It can meet the connection and positioning requirements of precision parts in instruments and meters, ensuring that the instruments can still maintain accuracy and stability in an environment with slight vibrations.

Marking Method of the Light-duty Rolled Elastic Cylindrical Pin

For example, a light-duty rolled elastic cylindrical pin with a nominal diameter \(d = 6mm\), a nominal length \(l = 30mm\), a material of steel (St), a heat treatment hardness of 420 - 545HV30, and a surface oxidation treatment is marked as: Pin GB/T 879.5 6×30. If the material is austenitic stainless steel (A), without heat treatment and with a simple surface treatment, it is marked as: Pin GB/T 879.5 6×30 - A.

Purchase Precautions for the Light-duty Rolled Elastic Cylindrical Pin

Dimensional Accuracy: According to the actual assembly requirements, select pins with dimensional accuracy that meet the requirements to ensure a reasonable fit clearance with the installation hole, so as to achieve good positioning and connection.

Material Performance: Select materials according to the usage environment and working conditions. For example, in a humid environment, stainless steel materials with good corrosion resistance should be selected. In occasions with large impact loads, the strength and toughness of the materials need to be considered.

Product Quality: Check the appearance, which should have no defects such as cracks, burrs, and deformations. At the same time, request the supplier to provide a quality inspection report to ensure that the product meets the relevant standards.

Installation and Maintenance of the Light-duty Rolled Elastic Cylindrical Pin

Installation: During installation, special tools such as a press-in tool or a punch can be used to smoothly press or tap the pin into the installation hole, avoiding oblique installation. For occasions with high-precision requirements, it is necessary to clean and lubricate the installation hole and the pin to ensure the smooth progress of the installation and the fit accuracy.

Maintenance: Regularly check the usage of the pin, and observe whether there are problems such as wear, deformation, looseness, or corrosion. If any, it should be replaced in a timely manner to ensure the normal operation of the equipment. For pins working in harsh environments, the inspection cycle can be appropriately shortened.

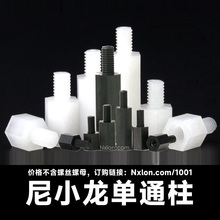

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

内4.2外7.0黑色塑料直通柱隔离柱

订购链接:Nxlon.com/1015

内4.2外7.0塑料直通柱隔离柱是一种用于电子设备等领域的绝缘零部件,尼小龙现有直通柱M4系列内径=4.2mm;外径:M4系列外径都是7mm;高度:2到15mm

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

塑料R型线夹圆形线卡拱形压线板

订购链接:Nxlon.com/1053

塑料R型线夹圆形线卡拱形压线板,材质:PP塑料、尼龙等。紧固孔:M4。塑料R型线夹圆形线卡拱形压线板,材质:PP塑料、尼龙等。紧固孔:M4。

尼小龙EHR塑料花瓣型护线套

订购链接:Nxlon.com/1050

塑料梅花型护线套EHR尼龙扣式线束圈花瓣形保护环卡电线出线孔塞材质:尼龙,颜色:黑色、白色;规格:EHR-16、EHR-19、EHR-21、EHR-22、EHR-25等。

绝缘透明塑料六角螺母

订购链接:Nxlon.com/1016

绝缘透明塑料六角螺母是一种采用聚碳酸酯(PC)材料制成的具有特定功能和特性的塑料螺母,尼小龙现有塑料螺母M3、M4、M5、M6、M8等公制规格。

R2024-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2024

R2024-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

R4050-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/4050

R4050-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

内3.2外7.0白色塑料直通柱ABS隔离柱

订购链接:Nxlon.com/1012

内3.2外7.0白色塑料直通柱ABS隔离柱是一种以ABS(丙烯腈 - 丁二烯 - 苯乙烯共聚物 )为材质的PC板隔离柱。