Large Washer for Self-tapping Screw Assemblies

©Nxlon.com D/T:

The large washer for self-tapping screw assemblies is a kind of washer used in conjunction with self-tapping screws, and it is usually used in connection scenarios that require a larger supporting area or higher sealing performance.

Relevant Standards of the Large Washer for Self-tapping Screw Assemblies

GB/T 96.1-2002: It specifies the plain washers with a nominal specification (major diameter of the thread) of 1.6 - 64mm, belonging to the large series, with hardness grades of 200HV and 300HV, and a product grade of Class A.

GB/T 9074.21-1988: It is applicable to the combination of cross recessed hexagon head self-tapping screws and large washers. However, this standard has been repealed and replaced by GB/T 9074.20-2004.

Structural Features of the Large Washer for Self-tapping Screw Assemblies

Shape: It is in the shape of a circular thin piece with a hole in the middle for the self-tapping screw to pass through, and it is flat as a whole.

Dimensions: The dimensional specifications match the self-tapping screws they are used with. Its inner diameter is slightly larger than the major diameter of the thread of the self-tapping screw, and the outer diameter is larger than that of a common plain washer. The thickness is usually between 1 - 5mm, and the specific value depends on different specifications and usage requirements.

Materials: Generally, it is made of metal materials, such as carbon steel, stainless steel, etc. In some special application scenarios, materials such as copper alloys or aluminum alloys are also used.

Working Principle of the Large Washer for Self-tapping Screw Assemblies

Dispersing Pressure: It increases the contact area between the head of the self-tapping screw and the connected component, making the pressure exerted by the screw on the connected component more evenly distributed, and avoiding damage to the surface of the connected component caused by excessive local pressure.

Increasing Sealing Performance: It can fill the tiny gaps between the screw head and the connected component, playing a certain sealing role to prevent liquids, gases, or dust from entering or leaking from the connection part.

Protecting the Surface: It prevents the head of the self-tapping screw from directly rubbing against the surface of the connected component during the tightening process, protecting the surface of the connected component from being scratched or worn.

Advantages of the Large Washer for Self-tapping Screw Assemblies

Strong Versatility: It can be used in combination with self-tapping screws of various specifications and is suitable for different connection requirements.

Convenient Installation: Just put the large washer on the self-tapping screw and then screw them together into the connected component. There is no need for additional complex installation tools or operations.

Low Cost: With a simple structure, a mature manufacturing process, and a relatively low material cost, it can effectively control the cost while ensuring the connection performance.

Application Fields of the Large Washer for Self-tapping Screw Assemblies

Mechanical Manufacturing: It is used for the assembly of the casings of mechanical equipment, the connection of components, etc., which can make the connection more secure and flat.

Electronic Equipment: In the production of electronic equipment, such as computers, mobile phones, etc., it is used to fix components such as circuit boards and casings, which can not only ensure the reliability of the connection but also protect the electronic components and the surface of the equipment.

Furniture Manufacturing: During the assembly of furniture, it is often used to connect wooden boards, metal components, etc., making the structure of the furniture more stable and avoiding damage to the wood surface caused by the screws.

Construction and Decoration: In the field of construction and decoration, it can be used to fix doors and windows, decorative panels, electrical conduits, etc., improving the stability and aesthetic appeal of the connection.

Precautions for Selecting the Large Washer for Self-tapping Screw Assemblies

Size Matching: According to the specifications of the self-tapping screws, accurately select the large washers of corresponding sizes to ensure that the inner diameter of the washer is suitable for the screw diameter, and the outer diameter can meet the requirements for dispersing pressure and sealing.

Material Selection: Determine the material of the large washer according to the usage environment. For example, in a wet environment or outdoors, stainless steel materials should be selected; in a general dry environment, the large washer made of carbon steel can usually meet the requirements.

Hardness Requirements: The hardness of the large washer should match the hardness of the self-tapping screw and the connected component. If the washer is too hard, it may damage the surface of the connected component; if it is too soft, the washer is likely to deform when the screw is tightened, affecting the usage effect.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

R2024-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2024

R2024-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

塑料芭蕾铆钉-尼龙宝塔卡扣

订购链接:Nxlon.com/1026

国标塑料铆钉芭蕾铆钉材质:POM、PC等;颜色:白色、黑色、透明;R型铆钉,芭蕾铆钉与宝塔铆钉起源于广东中山,它们都是一种简易铆接的塑料卡扣; 利用塑料的记忆性紧固两较薄的面板,铆定后可以再次取下,可重复使用。

R3045-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3045

R3045-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

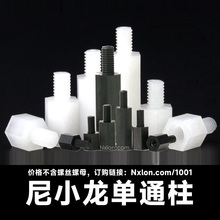

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!