External Sawtooth Lock Washers

©Nxlon.com D/T:

Structural Features of External Sawtooth Lock Washers

Shape Design: External sawtooth lock washers are usually circular in shape, composed of two inner and outer discs, with a sawtooth structure on the outer edge.

Size Specifications: According to different usage requirements, external sawtooth lock washers come in a variety of size specifications. For example, the GB/T 862.2-1987 standard specifies external sawtooth lock washers with specifications ranging from 2mm to 20mm.

Working Principle of External Sawtooth Lock Washers

Friction Fastening: During the assembly process, when the bolt or nut is tightened, the sawteeth of the external sawtooth lock washer will embed into the surface of the connecting piece, increasing the friction between the washer and the connecting piece. This effectively prevents the connecting piece from loosening due to reasons such as vibration and impact during use.

Elastic Deformation Fastening: The washer itself has a certain degree of elasticity. After the bolt or nut is tightened, the washer will undergo elastic deformation, exerting a continuous pressure on the connecting piece, keeping the connecting pieces closely connected and further enhancing the anti-loosening effect.

Materials and Surface Treatment of External Sawtooth Lock Washers

Material Selection: Common manufacturing materials include carbon steel, stainless steel, etc. External sawtooth lock washers made of carbon steel have high strength and hardness, which can meet the fastening requirements of general mechanical connections; washers made of stainless steel have good corrosion resistance and are suitable for corrosive environments such as humid, acidic and alkaline conditions.

Surface Treatment: In order to improve the rust and corrosion resistance and aesthetic appearance of the washers, surface treatment is usually carried out on them, such as blackening by oxidation, galvanizing, nickel plating, etc. The blackening treatment by oxidation can form a black oxide film on the surface of the washer, playing a certain rust prevention role; galvanizing and nickel plating treatments can form a metal protective film on the surface of the washer, effectively improving the corrosion resistance of the washer.

Application Fields of External Sawtooth Lock Washers

Mechanical Manufacturing Industry: In the assembly of various mechanical equipment, such as machine tools, cranes, conveyors, etc., external sawtooth lock washers are widely used in the connection parts of bolts and nuts to ensure that the connecting pieces will not loosen during the operation of the equipment, and to guarantee the stability and safety of the equipment.

Automobile Manufacturing Industry: Many connection parts of the engine, chassis, body and other parts of automobiles need to use external sawtooth lock washers, such as the bolt connection of the engine cylinder block, the connection of the chassis suspension system, etc., to prevent the connecting pieces from loosening due to vibration during the driving of the automobile, which may affect the performance and safety of the automobile.

Aerospace Industry: External sawtooth lock washers also play an important role in the manufacturing of aerospace equipment such as aircraft and rockets. Due to the extremely high requirements for reliability and safety of aerospace equipment, the excellent anti-loosening performance of external sawtooth lock washers can ensure that the connecting pieces always remain in a fastened state under complex flight environments.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

塑料螺丝保护套-螺母保护帽

订购链接:Nxlon.com/1035

塑料螺丝帽保护套-塑料螺母保护帽M8M10六角塑料螺母保护帽外六角塑料螺丝盖罩螺栓螺丝装饰防尘套,尼小龙螺母保护帽材质:聚丙烯 Polypropylene,型号:S-12-PP, S-13-PP, S-14-PP, S-16-PP, S-17-PP

R4060-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/4060

R4060-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

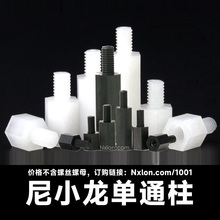

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

R3045-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/3045

R3045-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

R4050-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/4050

R4050-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。

绝缘尼龙铆钉-LRD-4-LRD-5塑料卡扣

订购链接:Nxlon.com/1019

绝缘尼龙铆钉-LRD-4-LRD-5塑料卡扣是一种常用于电子行业的紧固件,塑料铆钉直径:3.6mm,塑料铆钉头直径:7mm,公称长度:8.6mm等。

绝缘塑料法兰螺母

订购链接:Nxlon.com/1034

尼龙法兰螺母的螺纹规格有:M3*0.5、M4*0.7、M5*0.8、M6*1.0、M8*1.25、M10*1.5、M12*1.75等白色尼龙螺母、黑色塑料螺母、透明塑料法兰螺母。