Slotted Hexagon Head Bolt

©Nxlon.com D/T:

The slotted hexagon head bolt is a common type of bolt. The following is a detailed introduction to the slotted hexagon head bolt:

Structural Features of the Slotted Hexagon Head Bolt

Hexagon Head: The head of the bolt is hexagonal, which makes it convenient to use a wrench for tightening and loosening operations. The hexagonal design provides a large torque application area, ensuring that sufficient force can be applied during the tightening process. At the same time, it is also easy to operate in different spatial positions because various types of hexagon wrenches can be used, such as open-end wrenches, ring wrenches, socket wrenches, etc.

Slotting: There is a longitudinal slot on the head of the bolt. Its function is to be used in conjunction with a split pin to prevent the bolt from loosening during use. After the bolt is tightened, insert the split pin into the slot and spread the tail of the split pin so that it is stuck between the head of the bolt and the connected part, thereby restricting the rotation of the bolt and improving the reliability of the connection.

Threaded Part: Similar to the thread of an ordinary bolt, it is used to cooperate with a nut to achieve a tight connection. There are various choices for the specification and precision of the thread according to different usage requirements. Common ones include coarse threads and fine threads. Coarse threads are suitable for general tightening connections. They have a larger pitch and thread profile height and can withstand a larger axial tensile force. Fine threads are suitable for occasions that require higher tightening precision and smaller preload forces. Their pitch is smaller. Under the same bolt diameter, the number of teeth of fine threads is larger, so they can provide more precise control of the tightening force.

Specification Dimensions of the Slotted Hexagon Head Bolt

Thread Diameter: Common specifications include M3, M4, M5, M6, M8, M10, M12, M16, M20, etc. Among them, M represents the metric thread, and the following number represents the nominal diameter of the thread, with the unit being millimeters. Different application scenarios require selecting an appropriate thread diameter according to factors such as the thickness of the connected parts and the force-bearing situation. Generally speaking, for connections that bear a large tensile or shear force, bolts with a larger diameter need to be selected.

Bolt Length: The length specifications are quite diverse, usually ranging from a few millimeters to several hundred millimeters. Common lengths include 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm, 50mm, 60mm, 80mm, 100mm, etc. When choosing the bolt length, factors such as the total thickness of the connected parts, the thickness of the washer, and the thickness of the nut need to be considered to ensure that there is enough thread length for the bolt to cooperate with the nut after tightening, and the head of the bolt can completely fit the surface of the connected part.

Application Fields of the Slotted Hexagon Head Bolt

Mechanical Manufacturing: It is widely used in the assembly and maintenance of various mechanical equipment, such as machine tools, engines, speed reducers, etc. It is used to connect different components so that they can be fixed together and bear various forces during the operation of the equipment to ensure the normal operation of the equipment. For example, in the connection of components such as the bed and column of a machine tool, the slotted hexagon head bolt can provide a reliable tightening force, ensuring that the machine tool has sufficient rigidity and stability during the machining process.

Automotive Industry: In the production and manufacturing of automobiles, it is used to connect body structural parts, engine components, chassis components, etc. For example, the frame of an automobile is usually composed of multiple metal components connected by bolts. The slotted hexagon head bolt plays a key connecting role here, being able to withstand various vibrations and impact loads during the driving process of the automobile to ensure the strength and safety of the body. In addition, during the assembly of the engine, a large number of slotted hexagon head bolts are also used to connect various components, such as the cylinder block, cylinder head, crankcase, etc., to ensure the sealing and reliability of the engine.

Construction Industry: In building structures, it is used to connect steel structural parts, aluminum alloy door and window frames, etc. For example, in steel structure buildings, the connection between steel beams and steel columns usually uses high-strength slotted hexagon head bolts. Through friction-type connection or bearing-type connection methods, the steel structural parts are firmly connected together to bear the self-weight of the building and various external forces. In the installation of aluminum alloy doors and windows, the slotted hexagon head bolts are used to fix the door and window frames to the wall to ensure the stability and sealing of the doors and windows.

Electrical Equipment: In the installation and maintenance of electrical equipment, it is used to connect electrical components, the frames of distribution cabinets, etc. For example, in a distribution cabinet, various electrical components such as circuit breakers, contactors, and relays are usually installed on a metal frame and fixed by slotted hexagon head bolts. These bolts not only need to ensure that the electrical components are firmly fixed but also meet the insulation and grounding requirements of the electrical equipment to ensure the safe operation of the electrical equipment.

Materials and Surface Treatments of the Slotted Hexagon Head Bolt

Materials:

Carbon Steel: It has high strength and hardness and a relatively low cost, and is suitable for tightening connections with general requirements. Common carbon steel materials include Q235, 45 steel, etc. Q235 steel has good toughness and weldability and is often used in some occasions where the strength requirement is not particularly high. After appropriate heat treatment, 45 steel can obtain higher strength and hardness and is suitable for connections that bear a large load.

Alloy Steel: It has higher strength, toughness, and wear resistance and is suitable for occasions with high requirements for bolt performance. For example, alloy steel materials such as 35CrMo and 40Cr, after processes such as quenching and tempering treatment and surface hardening, can maintain good performance under harsh conditions such as high temperature, high load, and impact, and are often used in fields such as aerospace and heavy machinery.

Stainless Steel: It has excellent corrosion resistance and oxidation resistance and is suitable for corrosive environments such as wet and acidic or alkaline conditions. Common stainless steel materials include 304, 316, etc. 304 stainless steel has good corrosion resistance and versatility and is suitable for general corrosive environments. Due to the addition of molybdenum elements, 316 stainless steel has better corrosion resistance and pitting corrosion resistance and is often used in environments with high corrosion resistance requirements such as marine environments and chemical equipment.

Surface Treatments:

Galvanizing: A layer of zinc is plated on the surface of the bolt by electroplating or hot-dip galvanizing methods, which can improve the corrosion resistance of the bolt. The galvanized layer can form a dense zinc oxide protective film in the air, preventing oxygen and moisture from coming into contact with the bolt substrate, thereby preventing rust. Common galvanized layers include white zinc, multicolored zinc, black zinc, etc. The different colors are mainly caused by different surface passivation treatments, and their corrosion resistance also varies slightly. Generally speaking, multicolored zinc has relatively better corrosion resistance and is often used in outdoor or harsher environments.

Blackening: Also known as bluing treatment, it is a method of forming a black oxide film on the surface of the bolt through chemical oxidation. The bolt after blackening treatment not only has a certain rust prevention ability but also has a beautiful appearance and is often used in some equipment or components with appearance requirements. However, the corrosion resistance of the bolt after blackening treatment is relatively weak and is generally suitable for indoor or relatively dry environments.

Nickel Plating: A layer of nickel is plated on the surface of the bolt, which can improve the corrosion resistance and wear resistance of the bolt and at the same time give the surface of the bolt a good gloss. Nickel-plated bolts are often used in occasions with high requirements for appearance and corrosion resistance, such as in the fields of electronic equipment and instruments.

Installation and Disassembly of the Slotted Hexagon Head Bolt

Installation: First, pass the bolt through the hole of the connected part, and then screw the nut onto the threaded part of the bolt. Use a wrench to tighten the nut. During the tightening process, pay attention to controlling the torque to ensure that the bolt reaches an appropriate preload force. For situations where a split pin needs to be used, after the bolt is tightened, insert the split pin into the slot on the head of the bolt and spread the tail of the split pin so that it is stuck between the head of the bolt and the connected part.

Disassembly: Use the corresponding wrench to loosen the nut, and then remove the bolt from the connected part. If the bolt is rusted or difficult to disassemble, methods such as using a rust remover or heating can be used for treatment to reduce the friction between the threads and facilitate disassembly. During the disassembly process, pay attention to avoiding damage to the surface of the bolt and the connected part. If the split pin is difficult to remove, you can first straighten the tail of the split pin and then use tools such as pliers to pull it out.

尼小龙塑料螺丝-塑料螺母-尼龙垫圈-塑料铆钉

尼小龙塑料SB通孔扣式护线套

订购链接:Nxlon.com/1051

绝缘塑料SB通孔扣式护线套16-19-22-25尼龙电缆电源线塑胶线孔盖质:尼龙,颜色:黑色、白色;规格:SB-16、SB-19、SB-22、SB-25等。

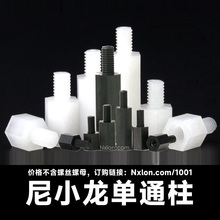

绝缘尼龙单通六角隔离柱

订购链接:Nxlon.com/1001

绝缘尼龙单通六角隔离柱:M2.5 M3 M4尼龙单头六角单通柱隔离柱采用先进的立体蜂巢结构全自动化脱模模具工艺高效成型!尼龙柱内螺纹是一次性注塑成型,不易滑牙!

R2648-塑料铆钉-尼龙铆钉

订购链接:Nxlon.com/2648

R2648-塑料铆钉-尼龙铆钉塑料铆钉-尼龙铆钉-汽车塑胶铆钉-尼小龙尼龙铆钉R2.6R3.5R4R5塑胶柳钉子母铆钉快捷紧固件塑料卡扣。